#firesafeballvalves #API607firesafevalves #firesafevalvemanufacturer #api607ballvalve

The purpose of fire safe is to maintain a strategic distance or to overcome the passage of flammable fluids (liquid or gas or gas surrounded by liquid phases), in any case at a given time and in any case not in the separation of aggregates in the middle of this period, A closed valve in the middle of the pipe has overheated, caused by a fire or similar event. Sensitive hazard reviews indicate when fire dampers should be used. When you are forced to use one, you must comply with all principles, regulations and laws related to the method, plant, pipeline, vessel or unusual craft you have. Check if safe ordering is required or just a safe configuration without actual ordering tests.

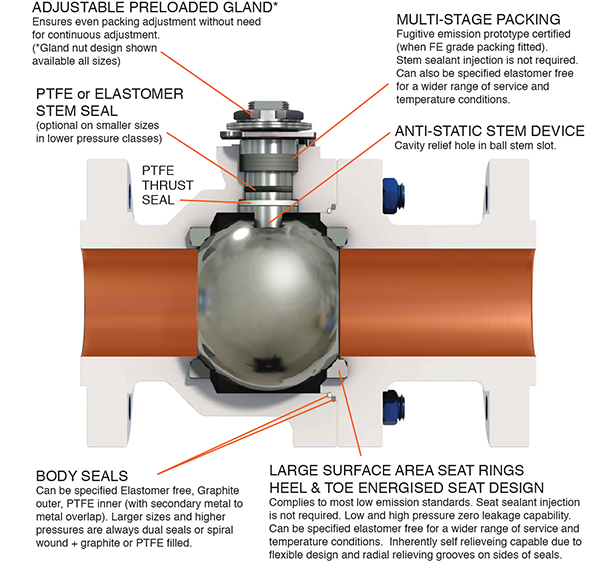

Fire Certified Ball Valves: CARBONVALVE offers Fire Certified Ball Valves in accordance with ASME/API 607 Fifth Edition, passed June 2005. A similar standard is ISO 10497-5:2004. The standard is titled "Fire Testing of Soft Positioning Angle Rotary Valves". Fire safety valves were in place when the factory fires occurred; the delicate seats were all burned out, and the valves were still held in place by precise balls and bodies. This will keep evil at a cautious level.

Results for 3/4-Way Fire Safety Valve: Fire safety testing requires the ball to be at right angles to the port after termination to prevent internal spillage. For a 3/4-way valve, you'll have 3 holes, but a ball comes out. That's why no one can operate it, the balls sticking out can't block 3 or 4 ports. The result provided by CARBONVALVE is the use of suitable seals on the multi-way valve to avoid external spillage during termination and 3 or 4 fire dampers on each port. These 2-way fire dampers will block fluid through their fire profile.

CARBONVALVE is a manufacturer of ball valves, gate valves, globe valves, check valves etc for more than 10 years.